Here's a part of all four Freshwater Class Ferries that most passengers will probably never see. Undergoing the most extensive overhaul in it's 29 years of service, Collaroy's radial davit is used to lift, swing and lower the ferry's rescue boat into the water in times of emergency. It has an electric winch for lifting and is rotated by a hand operated slewing motor, both of which have been removed for servicing. It is not normally capable of swinging this far inboard, and is only able to do so here because the fixed electrical wiring supply conduit which normally restricts it's inboard swing has been stripped away to allow full preservation of the davit arm.

A yard rigger rises up from the dock floor in a cherry picker. Stability of these rigs is rarely challenged - this model sits on a 15-tonne base, it's tyres are foam-filled and the boom extensions are all made of high-tensile steel.

The first of Collaroy's four forward propellor blades is unbolted from its crank plate and will be walked sideways before being lowered down to the dock floor with the help of a forklift. After each blade is removed, the shaft is rotated to move the next blade into the top position, and the process is repeated until only the hub remains.

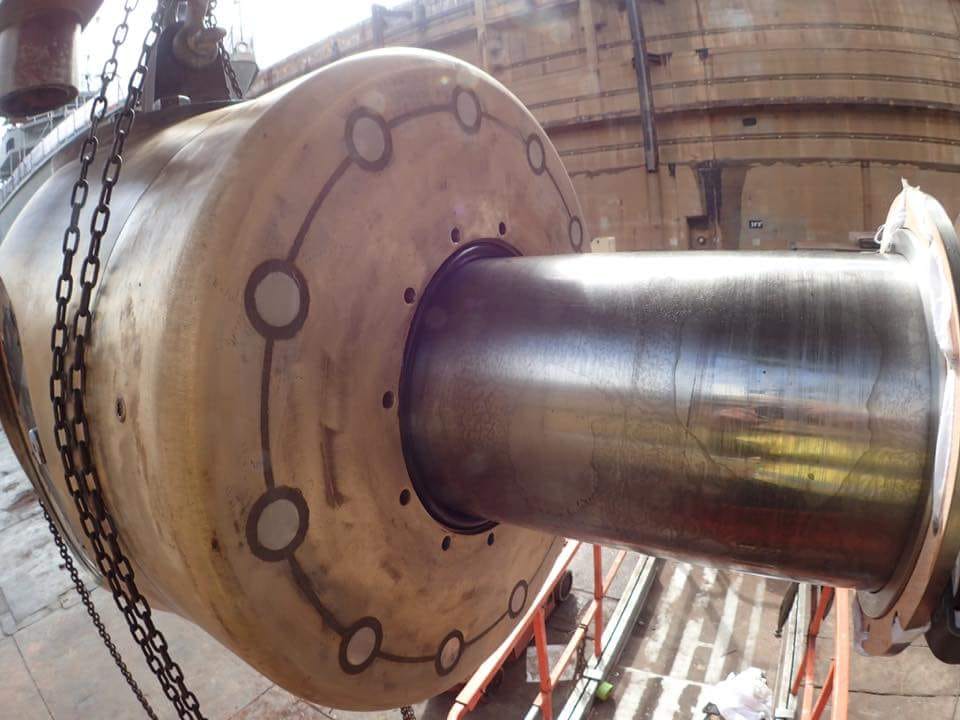

All four blades off, only the masked-up propellor hub remains at the end of Collaroy's forward propellor shaft. What you see here, between the inboard face of the hub and the outboard end of the turret-like stern tube, is the external stern tube seal. Bolted to the inboard face of the hub, at right, is the seal's white-metal liner which follows the rotational movement of the shaft and hub. At left, bolted to the outboard face of the stern tube, is the mating part of the stern tube seal, which contains four highly-engineered sealing rings. This stationary part of the seal compresses the four internal sealing rings onto the liner's exterior diameter while it and the shaft rotates. The ingeniously designed result, conveniently known as a LIPS seal, is an unbreakable standoff, while rotating, between the pressure of the seawater pushing inwards and the pressure of the stern tube oil pushing outwards.

On the fitter's workbench, Collaroy's aft outer stern tube seal. Here showing evidence of wear, the white-metal seal liner, at left, slips into the seal housing at right. The seal housing, which disassembles like a layer cake, will be cleaned by yard fitters, fitted with new seals and then inspected by the ship surveyor. The outgoing LIPS seals are visible here inside the seal housing.

In classic fashion, a yard fitter measures the outer diameter of Collaroy's aft outer stern tube seal liner.

Collaroy's new main deck ceiling panels are nearly fully fitted.

The surveyor knows where to look. Collaroy's aft propellor hub is dissected just a bit further to reveal the actual transition point where the shaft's lineal section transitions out radially to form the wider, platelike surface through which the bolts pass that join it up to the hub assembly. That transitional section, painted white and undergoing a fatigue test here, is where the enormous amount of torque caused by the drag of the propellor blades, especially through pitch alteration, is most likely to create metal fatigue in the shaft. If you've heard seemingly unbelievable stories about ships' propellors "falling off" they are most likely based upon failures in this section. There were no issues here.

Suspended under a canopy of two and five-tonne chainblocks, here is the enormous multi-phase coupling, deep inside the ship, which joins Collaroy's outgoing nine-tonne tailshaft segment to the commanding mechanisms which not only cause it to rotate but also push and pull pressurised oil through it's dynamic central galleries to create pitch alteration of the four propellors at it's end. We say it's enormous, but how do we show you? Look closely at this photo and see the yard fitter just above the green coupling. He is actually standing up beside the coupling, using a pressurised oil jack to force out the locating pins which help to perfectly marry the coupling together. Once the pins are out, there will be bolts. Then it's on to the second of three sections

Collaroy's four forward propellor blades, all cast in 1987, have been polished. After polishing, the surface is ripe and ready to absorb the dyes that will be used to penetrate the metal and, in effect, magnify any internal flaws or signs of fatigue or stress - which is whole reason why they were removed from the hub.

If there is any serious stress, strain or fatigue in Collaroy's number one aft propellor blade, the area around the bolt housings and the transition zone from the heel up to the blade face are the areas where it is most likely to register. When you think about how the blade does it's work, it makes sense.

Collaroy in the dock. Stabilisers back in, interior lighting beginning to come back to life and anchor chains that look like termite galleries as they still lie flaked onto the dock floor. Some distance in the background, morning peak begins for ferry traffic on Sydney Harbour.

Brighter times are already beginning for Collaroy's interior passenger areas. Tired and dated fluorescent ceiling lighting fixtures have given way to new, more dependable LED units. Painting is finished in these upper deck areas. Soon, the multicoloured protective layer of floor covering, which has certainly served its purpose this time, will be lifted up and taken away to reveal the brand new flooring beneath it which was laid down in the four-week pre-docking period at Collaroy's home shipyard in sleepy old Mort Bay.

Only a mother could love it. At every docking, there comes a point in the hull and superstructure painting timeline where the vessel looks about as weary and humbled as it possibly could. If not for the fresh lettering on the funnel, all surface areas still appear to be on the downward trend. The measles of widespread undercoating will soon start to give way to layers of final colour. Note the amount of scaffolding which must remain in place at the top of the ship just to enable the painting of the laid-down masts and monkey islands.

The two gigantic rotary pistons have been lifted out of their port and starboard veins within Collaroy's Forward Tenfjord Steering Compartment. They will be craned off the ship for machining.

Collaroy's aft propellor shaft has been returned almost fully into position. It will take fitters within the ship almost two full working days to work their way through the surgical process of connecting it back up to the drive systems. Here, the outer stern tube seal is nearly in situe. A black temporary spacer (at about 4 o'clock on the seal housing) has been installed between the seal housing and the liner to prevent the tapered liner from travelling any further into the seal housing. The spacer has established the working distance between the liner and the seal housing. As the propellor hub progresses further into the tube to it's final position, it will meet up with and be bolted to the outboard face of the liner, shown here with it's gasket loosely tied on with rags, in the ready position.

The inboard face of Collaroy's aft propellor hub. Being fully re-assembled after it was split apart for fatigue testing means that the vacant spaces around the bolts within their housings in the cover plate must be filled with anti-corrosive cement and skimmed flush. The grout-like darkish coloured cement sets here while the shaft moves slowly inboard. The outboard face of the seal liner is shown at right, waiting for the hub to arrive so the two can be bolted together to complete the reconstruction of the outer stern tube seal.

Only the early birds would see this. Hull painting crews working late into the day yesterday. South side dock floods were left on to illuminate superstructure for more spot undercoating, with initial top coats of "Fleet Sand" beginning to appear in higher areas.

Standing room only. Collaroy's forward shelter deck is masked and ready for a few new layers of non-skid coating on the deck. Seating patterns on both shelter decks have been altered slightly, with aisles widened to ease passenger flow.

While Collaroy's anchor windlass continues it's off-ship odyssey through the blast shed, boilermaker, machinist and paint shops, it's forward deck home is getting a much needed preservation session as well.

Collaroy's navigation decks are being stripped back to bare aluminium plating and re-covered with a non-slip sealing coat which is designed to bend and flex with the deck plating underfoot. To carry out the removal of the old surface, the preservation team has unleashed some of its fiercest weapons, the most notorious of these being the abrasive suction pressure mower and the ultra high pressure water blaster lance, which dispenses pressurised water at 34,000 psi - more than enough to cut through the steel capped boot of a careless operator.

Collaroy's aft propellor shaft is now fully recoupled within the ship. With the hub now in position, the outer stern tube's liner is finally bolted up to it's final position on the inboard face of the propellor hub. It is now easier to see how the liner, bolted to the spinning hub, is the rotating part while the seal housing, with it's three internal spring seals, remains fixed. Mounting bolts have been moused in classic style. Look closer to see the seal housing stamped with the seal's original manufacture date of 31-AUG-87

Collaroy's aft hub has returned home and now awaits the return of it's four 367kg propellor blades.

Collaroy's aft steering gear is coming back together as the hull painting timeline progresses around it. The Becker Rudder blade, secured in an upright position 100-meters away on the dock floor, will soon be lifted up and rejoined to the stock; first it will be hydraulically forced onto the stock's tapered tail section and then locked onto it using a 40 kg nut which will travel up along the thread hiding under all that black tape. What is the function of the second, smaller pin protruding from the hull next to the stock? It is an essential part of the Becker Rudder design, and when we post the upcoming dock trial footage of the swinging rudder, all will be revealed.

Mechanical surgeons stitching up the patient. Fitters prepare to box up Collaroy's aft steering compartment. The internal areas have been virtually purified and kept pristine in preparation for the closing. To operate efficiently enough to adhere to survey requirements, the rotary veins inside will require a medium of oil continuously pressurised at 50 bar. Mating surfaces are painstakingly prepped and cleaned to ensure the integrity of the seal created when the 600kg cover is lowered and affixed.

Collaroy's forward propellor shaft is now uncoupled and eased out just enough to drain away the oil from the stern tube. The oil will weep out for hours before it slows to a trickle. All of Collaroy's discarded oils, of all types, are drained down from the ship into cubic receptacles like the one below the shaft here.

Yard boilermakers and painters team up to mark Collaroy's anchor chain into sections. Port and Starboard chain lockers each contain seven "shackles" of chain. Each shackle measures 90 feet/27.5 metres/15 fathoms. Shackles are joined together by a Kenter Shackle. Joining areas are marked so deck crews will know how many shackles are out of the locker. This is the start of shackle 6, marked not only by the white paint out to the sixth link on each side of the Kenter Shackle, but also by a layer of thick canvas banded twice into those links by 316 stainless banding - a backup marking system designed to keep the indicator alive should the paint fade or corrode away. This marking system looks easy enough to read, but it's not as easy as you might think to track the marking when the anchor has been released and the chain is literally flying out of the locker.

Yard riggers and fitters carry out the delicate and often time-consuming task of re-installing Collaroy's steel lower deck gangway ramps. Here, newly-machined pins and bushings with very tight clearances must be tediously re-aligned while the ramp dangles from the crane on a gusty day in the dock. This gangway alone required almost an hour to re-attach.

Collaroy's anchor windlass has been almost completely dissected. Everything but the gearbox was pulled apart. All components were cleaned up and painted. Both broke drums were built up and turned back down to as-new diameters, new brake banding installed and two newly-modified 316SS brake spindles.

New ceiling panels are all now in place on Collaroy's Main Passenger Deck. Combined with all new LED lighting fixtures and fresh paint, the upgrade of interior areas is on schedule.

Suspended from a gallery of two and five tonne chain blocks, Collaroy's nine-tonne forward propellor shaft reaches the changeover point. Shortly, the 32-tonne forklift will raise a custom-built supporting cradle up to take the weight of the hub, taking it's enormous weight off the chain blocks rigged to hull eyes. Then, freed from shipborne suspension, the shaft can travel the remaining distance out of the stern tube by means of the forklift slowly reversing out whilst riggers maintain a point of simple sliding suspension above the stern tube opening as the shaft moves out.

On a chilly overcast day in the dock, riggers work to extract Collaroy's forward propellor shaft.

Collaroy's forward shaft, fully emerged from the stern tube.

Keen-to-progress hull painters have been waiting for riggers to finish their work in the dock, and for protective tarps and covers to be on place over all the sensitive parts on the dock floor. The coast now clear, things are already changing.

Hull coating has taken a great step forward. Final coats of "STA Ferry Green" have been sprayed and rolled on after the entire hull was keyed with palm sanders. Detainers move in soon

Collaroy's navigation decks have all been stripped back to bare aluminium plating. The first coat of red-coloured preservative has been laid down. -->> Go to Collaroy 2018 Dry Docking Part 3

-->> Go to Narrabeen 2017 Dry Docking Part 1

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||