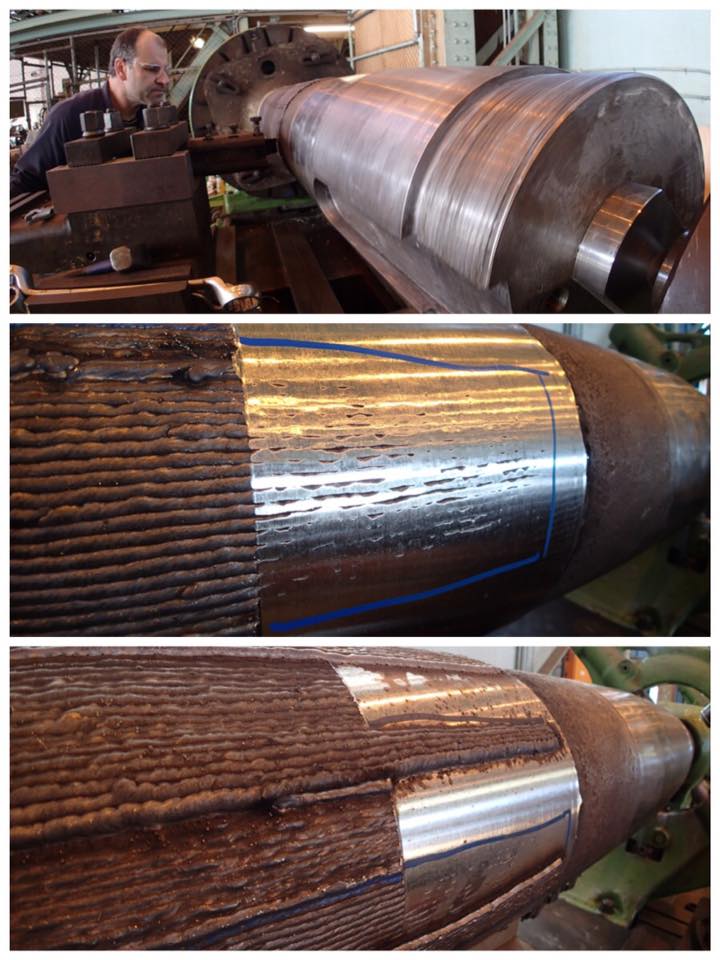

Thirty minutes of re-machining at just one end of the damaged area was all it took. The fitters could then plainly see that a second phase of welding/machining would be required to build up enough shaft diameter. Another 50kgs of rod has been ordered by the foreman and the welders have been at it nonstop since the call was made.

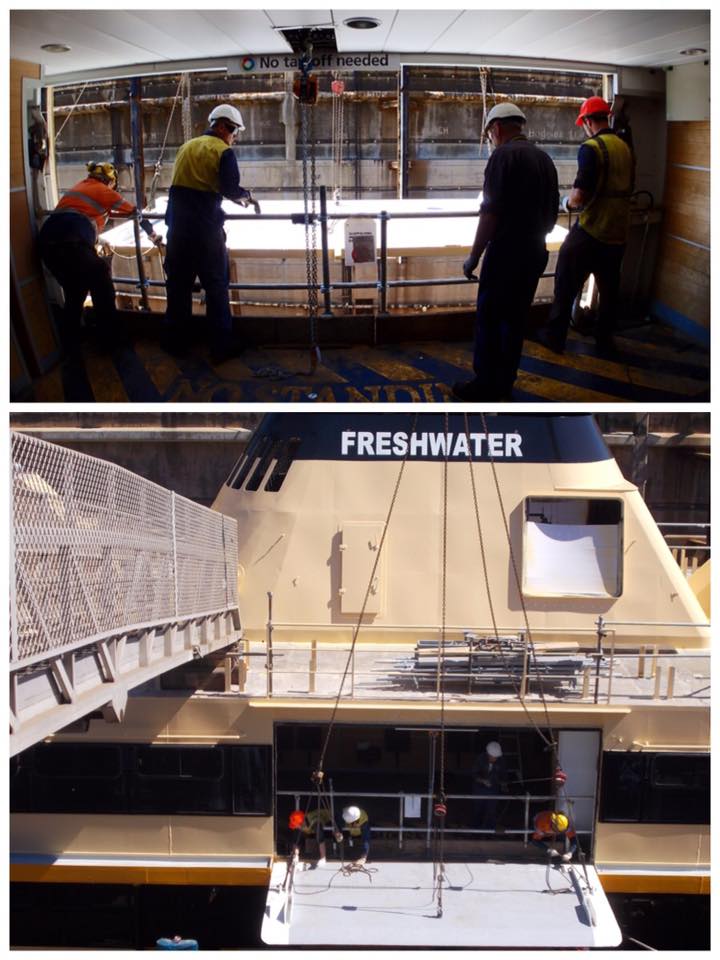

Freshwater's anchor windlass will be craned back down onto the pedestal today. The anchor pen has been receiving plenty of attention from the painters in preparation.

Freshwater's upper deck passenger gangways are aluminium, not steel. Their surfaces are still being stripped back and recoated with a base protection layer before a new anti-slip surface is applied.

All good at the other end. Freshwater's aft rudder stock is already in position and here go the fitters carrying out the last delicate job of placing the cap back on the steering box. Then they will evenly drive in 120 hex cap securing bolts, all to torque, all by hand.

The painters have the best view of the superstructure. The first coat of black anti-fouling paint has been applied to the waterline-and-down hull, while the final patches of primer dot the waterline-and-up green sections. Newly-machined propeller assembly has been wrapped heavily in protective masking.

Outgoing old zincs, installed 2010, above. New zincs about to be attached to spend the next five years underwater. If you don't know what these are for, ask a sailor!

Putting it all back together. The Freshwater's 2-tonne anchor windlass being craned back on board after being overhauled and painted.

Lifting and landing the windlass is all in the hands of the riggers.

Anchor chain has been surveyed and repaired. Seven shackles per side, all newly marked, ready for loading into the chain lockers tomorrow once the windlass in back in action.

Freshwater's aft rudder arrives by forklift, ready to to be brought up and bolted to the already-in-place aft rudder stock.

After preparing the mating surfaces properly so they can be easily separated in 2020, the rudder is eased up into the locating pins and joined to the stock. It will then be brought up tight with chain blocks, the two tapered pins will be dropped and the six numbered bolts will be refastened.

Sulphur Crested Cockatoos perched atop the south end of the dock, swoopingly watching the crews descend down the 76 stone steps each morning. No wonder hard hats are compulsory here. The last of the dark green colour will be rolled on today.

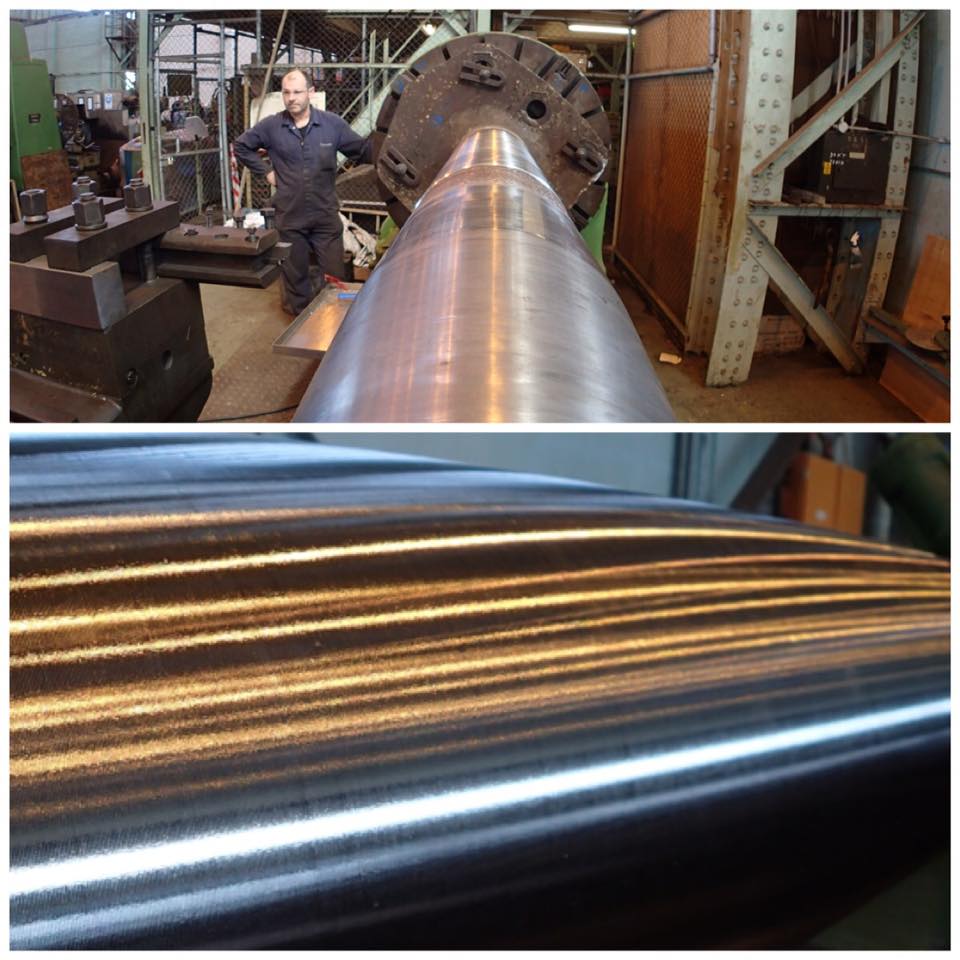

Machinist is satisfied. Surveyors are satisfied. After having over 60kg of stainless rod welded onto it and 80% of that amount machined back off, the Freshwater's forward rudder stock is finally ready to put back into service

After being slung perfectly flat by the riggers down in the dock, The Freshwater's upper port gangway ramp is craned back up into position and carefully aligned onto its pins.

The painters are closing in on completing the painting of the hull and superstructure.

Now that the final coats of paint on the hull and rudders have set, the new zinc anodes can be affixed. Below the waterline, there are no areas left beyond their protection. A pair of them is bolted to the base of each rudder, and there are a total of 35 spread throughout the hull.

The last groups of Freshwater's hydraulic steering motors are craned back down onto the vessel's decks, where the riggers and their chainblocks are waiting to carefully walk them back into the tightly confined spaces from which they have all come.

The Freshwater's shadow will disappear for another five years when we refloat the vessel, probably by Wednesday.

The crane drivers have to see everything. This should give you a good idea of exactly were we are.

In the hot midday sun, the riggers ease the Freshwater's starboard upper gangway into position.

After all the fuss over its repair and recertification, the Freshwater's forward rudder stock finally being craned back into the dock barely seems to make an impression .

The final few pieces can now be put back into the puzzle. The Freshwater's forward rudder stock sits on the floor of the dock. Today it will be rehoused, and then the rudder will be bolted up onto it once the stock is finally joined into the steering box and tested.

Both lengths of anchor chain have been hauled back up into the chain lockers. Now the anchors are standing tall to await their final prep and paint.

Freshwater begins its final few days on the blocks. The crane dropped this 32-tonne forklift into the dock a few days ago, and since then it has been re-organising the keelblocks around us in preparation for the docking of the next vessel, a dredge with our same length and beam but much heavier than us. We are getting the bum's rush.

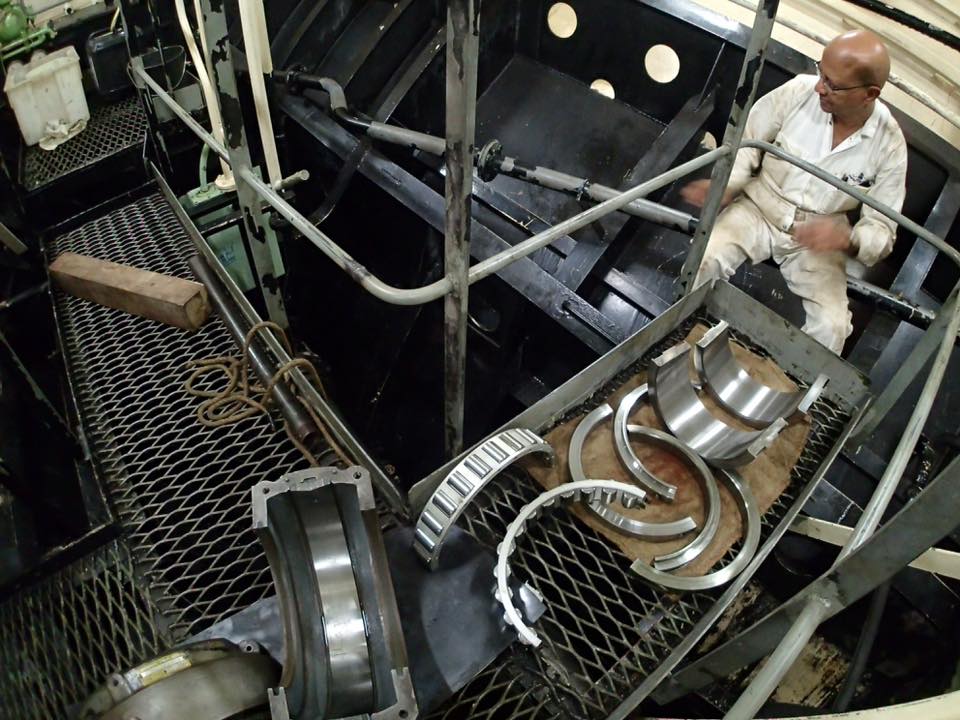

All internal. Servicing one of the ship's ten main shaft bearings. Each of these Cooper Bearings weighs over 40kgs and has to be disassembled into twelve interlocking parts. To service just one of these bearings, half of which are in need of replacement, the fitters temporarily lift the shaft up with a 100-tonne pneumatic jack.

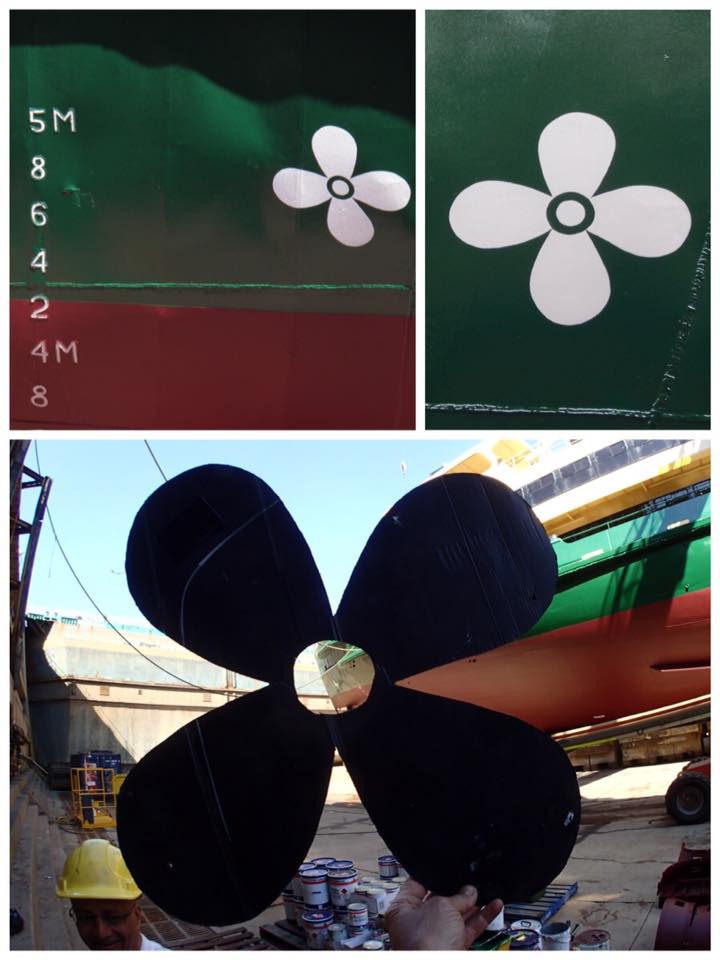

This is how they do it. Even our four propellor icons are done with precision.

Trying out a new method this time when it comes to painting our decks. Limiting the range of the anti-slip safety grit to only those areas where it is needed, and keeping it away from limber holes and scupper mouths. This will help to more freely allow seawater - and Manly Beach sand - to escape our decks, quickly back over the side.

The final strokes of the painter's brush.

These indentations in the ship's rudder are an indication of its internal construction. The rudder is not solid but in fact hollow, and has a cagelike internal 'skeleton' which prevents it from collapsing from the constant pressure of submersion.

In the boiling hot sun, the final assault of deck surface stripping terror is unleashed upon the Freshwater's navigation and bridge decks. The dreaded orbital suction mower. This savage primate will strip up the entire compliment of the old, degraded zinc chromate surfaces from the decks and take them back to pre-2002 bare aluminium. The key feature of this beast is that it instantly collects and removes all of its own spoil, ensuring that all of the freshly-painted decks and hull directly below are kept free from the ugly, damaging affects of the milky grey runoff.

Soon after the fury of the suction mower has passed, the Freshwater's port side navigation deck is blown dry, allowed to sun dry and then roll coated in red-coloured primer.

A visit from the fleet commodore. Chook Macdonald arrives for a bit of photo documentation

One for the crew. Even when being hauled up from the dock, the Freshwater's port anchor refuses to come up into the pipe properly. -->> Go to Freshwater 2015 Dry Docking Part 3

-->> Go to Narrabeen 2017 Dry Docking Part 1

-->> Go to Collaroy 2018 Dry Docking Part 1

| |||||||||||||||||||||